One Tool, Many Names: Coating Thickness Gauge, Paint Gauge, Paint Meter, etc,.

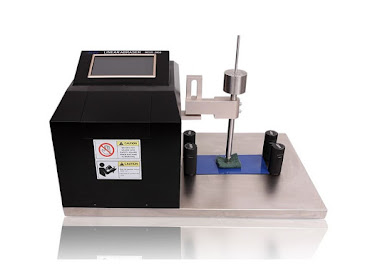

We have seldom experienced so many names attributed to a tool as is the case with this one – Coating Thickness Gauge. One reason for the many names is its use in quite many industries for quality assurance and conformance with international standards. It is one of the most important tools in many coating systems and procedures. Coating thickness gauges are used for corrosion inspection on steel structures – mainly metals, where they also have names like paint gauges, paint meters, dry film thickness gauges, etc. Coatings are applied on steel structures to improve surface properties, hence resist corrosion and other mechanical damages and the Paint gauge is used to non-destructively measure the thickness of applied coating – when the coating is dry.

This is also the case in the automobile manufacturing and production where multiple layers of paint coatings are used on car panels and other interior parts to avoid corrosion/wear and tear over time. While this industrial application has a similar nomenclature for a coating thickness gauge, the Automotive aftersales market has developed other names over the years such as Mil Gauge, Mil depth Gauge, Paint depth Gauge, Car paint meter, Mil Tester, Dft Gauge, etc, are all used to identify one tool and the testers used and named as washability tester, rockwell hardness tester, brinell hardness tester. Car buyers, used car dealerships, claims adjusters, and body shops will want to know whether there is concealed rust and repairs without actually damaging the paint on the car panel by using a Paint meter to measure the thickness of the paint, then check for thickness consistency. Inconsistency of thickness measurements on different car body parts might be an indication of rework on the car body to hide issues from mechanical damage.

One impact that the increasing number of names has had over the years is the difficulties involved with identifying the keywords customers use when searching for this tool or other tools like brinell hardness tester. Whereas the somewhat older nomenclatures are still searched for, new names are also becoming important. Also, the variety of names can be a problem, as gauge suppliers are forced to spend more trying to identify the best keywords (names) for their SEO campaigns. In the same regards, Coating thickness gauge suppliers might use keywords that are obsolete in their endeavor to achieve better organic rankings.

What other names do you use in your industry for Coating Thickness Gauges? And, Can you think of another quality control tool with so many names?

Comments