Coating Thickness Gauge: Everything You Need To Know

A coating thickness gauge helps find a lot about coatings by evaluating their thickness. In the global paints and coatings industry, coating thickness gauge helps determine the age, performance, and expected life of coatings. A dry film gauge is mostly preferred to evaluate the cost and quality of the coating process.

Measuring thickness with a dry film gauge

Also known as a paint meter, a dry mil gauge under the non-destructive thickness measurement category works on a simple, straightforward concept which doesn’t require any damage to the substrate or the coating. With a range of non-destructive dry film gauges, one can easily measure coating thickness. This method is not only cost-effective but over the years, it has also become a preferred choice for coating thickness measurement. On the other hand, the destructive coating measurement method involves cutting to the substrate. This is an expensive and time-consuming method.

With the help of the right coating thickness gauge, one can easily measure coating thickness on magnetic steel surfaces as well as non-magnetic metal surfaces. On ferrous metals such as steel, electromagnetic induction is widely used for effective measurement. Similarly, for non-ferrous substrates with non-conductive coatings, Eddy current principle of thickness measurement is applied.

Choosing the right coating thickness gauge

With a wide range of coating thickness gauges available online and offline, it can be daunting to decide on the best one. However, with companies like TestCoat bringing high-quality coating thickness gauges online in one place, it has become easier than ever. One can easily find a wide array of inspection equipment online for industrial use.

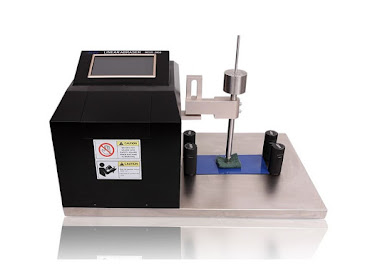

Paying attention to the design becomes crucial, particularly when you’re choosing measurement equipment. A coating thickness gauge usually consists of one display panel and a sturdy body. However, not all the products are equally made, and even a minor inaccuracy can create havoc on the entire production and supply chain. In order to choose the right one, here’s what to look for:

Robustness and resistance: Check if the dry film gauge is capable enough to measure accurately in different working conditions including operational temperature variations. Check if the device is dust and splash resistant, and the display is strong enough to stand up to minor wear and tear. An IP rating on a device can help you check its resistance characteristics. Similarly, check for chemicals and scratch resistance for the device’s display.

Measuring: Look for measuring modes the device supports. Most dry mil gauges support multiple modes such a single and continuous measuring mode as well as combined measuring. Depending on your needs, check the features you would be using the most.

Software and Adjustments: When buying a coating thickness gauge, look for a device that is backed by a well-developed, fully-functional software application. This will not only help you manage data efficiently, but you will also get assurance about its performance and future firmware updates. One should also check for point adjustment range when choosing a dry film gauge.

Bottom line

A coating thickness gauge comes in many designs and sizes, hence the product prices vary from product to product and manufacturer to manufacturer. Always look for reliable sellers offering high-quality products at affordable prices. Also, don’t get confused with the names such as dry film gauge, paint meter, dry mil gauge as technically they all are the same.

About TestCoat:

For many years, TestCoat has been a trustworthy partner and leader in the supply and distribution of inspection equipment, laboratory & physical test equipment for the coatings and paint industries. We supply non-destructive quality control and testing instruments such as Paint thickness Mil Gauges, Gloss meters, portable and benchtop metal hardness testers, laboratory mixersviscometers, film applicatorsdrying time recorder, cupping testers, Wet scrub abrasion testers, Coating inspection kits with advanced technology, and of the highest standards.

For more information, visit https://www.testcoat-usa.com/

Comments

Post a Comment