Choose The Right Hardness Tester: The TestCoat Guide

The hardness of a metal is its resistance to permanent deformation or its surface strength. This property is important when selecting which metal is best for the job. The Rockwell hardness test measures how resistant a material is to permanent indentation from a hardened steel ball at room temperature. Knowing how hard your materials are will help you make informed decisions about what type of metal works best for your application.

If you are the type of person that likes to know all the facts before making decisions, then this article will be perfect for you! In it, we take you through everything you need to know before purchasing and using your own Rockwell hardness tester.

What Is The Rockwell Hardness Test?

Many people like to use the Rockwell test because it is an absolute hardness test. Absolute hardness measures the actual ability of a material to withstand indentation without permanently deforming. By using this information, it allows manufacturers to make educated decisions about which metal is best for their application.

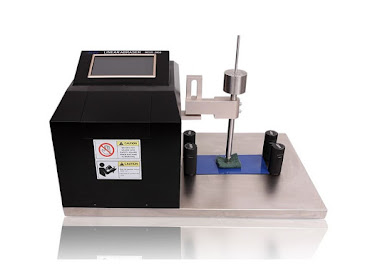

The digital Rockwell hardness testing system determines the hardness of a metal by measuring the depth (in millimeters) that a hardened ball indents a sample at room temperature. This test provides a quick, cost-effective way to determine how hard your materials actually are before making your purchasing decision.

Rockwell Hardness Tester Uses

The Rockwell hardness test is used for engineering, manufacturing, and quality assurance. It tests the hardness of metals and other materials. The portable Rockwell hardness tester lets you know how hard your material test piece is in comparison to other metals and materials. It can help you determine which metal is best for your application or if a material will hold up to the forces of nature while being used. Here are some common uses:

Quality assurance- In this area, businesses rely on the Rockwell hardness test to make sure that parts are up to specifications. For example, engineers can use this information in order to monitor the quality of metal parts during the manufacturing stages. They can see if these parts will be able to withstand the forces of the environment and still perform at their best.

Metal samples- Companies like to use portable metal hardness testers on their metal samples in order to find out what type of metal will be used for different applications. For example, a car manufacturer might want to know how strong a certain alloy will be when it is exposed to high heat.

Engineering- Engineering professionals also use the Rockwell test in order to make sure that they are using materials that are suitable for a particular application. For example, geologists must have extremely accurate information about which metals are suitable for cutting through rock when drilling oil and gas wells.

With all of these uses, the Rockwell test allows companies to benchmark their own materials in comparison to those of their competitors. It lets them figure out which metal is going to be the best for a given situation.

Before You Start Your Rockwell Test

Rockwell hardness testing is very easy to learn, and many people have wondered how they can do it themselves. However, even if you think you already know how this test works and what its uses are, there are still some important things that you should know before you get started. Here are some things that you should keep in mind before using your own Rockwell hardness tester:

The Rockwell hardness tester must be calibrated every time that it is used.

Before using your Rockwell hardness tester, make sure that it is calibrated correctly. A calibration certificate must be printed from the manufacturer's website for each tester. You'll typically need to bring the certificate with you when you purchase a Rockwell hardness tester, and the calibration process must be done in person at a certified testing laboratory.

Expect to pay somewhere between $100 and $500 for a quality device.

There are many ways to purchase your own Rockwell hardness tester. You can usually find specialty testers online, especially on TestCoat. You can get high-quality, reliable products at affordable rates and you can also get peace of mind as the products available here come with a warranty.

About TestCoat:

For many years, TestCoat has been a trustworthy partner and leader in the supply and distribution of inspection equipment, laboratory & physical test equipment for the coatings and paint industries. We supply non-destructive quality control and testing instruments such as Paint thickness Mil Gauges, Gloss meters, portable and benchtop metal hardness testers, laboratory mixersviscometers, film applicatorsdrying time recorder, cupping testers, Wet scrub abrasion testers, Coating inspection kits with advanced technology, and of the highest standards.

For more information, visit https://www.testcoat-usa.com/

Comments

Post a Comment