Coating Thickness Gauge - Why You Need Them and How Measuring Methods Work

The coating thickness gauge is a device used to measure the thickness of coatings on metal surfaces. These gauges are frequently used by automobile parts manufacturers and metal fabrication shops that manufacture products for various industries.

A coating thickness gauge is a product commonly found in machine shops, where it is often utilized in conjunction with the tape measure to determine the proper dimensions of a piece of material before applying it with filler paste or epoxy.

With its help, individuals can accurately assess how much material they need to apply in order to achieve their desired results while working on different surfaces including metal, wood, vinyl, and other waterproof materials.

Although there are a variety of coating thickness gauges available on the market today, they share one common goal: to determine the thickness of coatings applied onto different types of surfaces. However, these devices vary in what they measure and how they go about it.

Coating thickness gauges can be differentiated from other tools that are used for coatings and laminations based on their ability to measure widths, lengths, diameter measurements, etc.

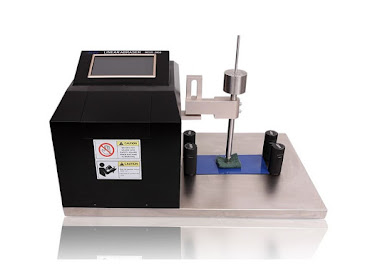

A digital coating paint thickness gauge is a device that measures coating thickness using smart measuring technology. With a display unit installed in the head, the user is able to monitor coating level output by simply looking at the monitor display screen on the gauge.

The digital coating paint thickness gauge is ideal for use by experienced users and provides accurate results. As a result, it improves the ability to manage the knowledge of their coatings and laminations.

Various manufacturers have different models for calculating coating thickness according to their unique needs. These devices offer a wide range of features that include: inclinometer, programming, cleaning, and counting functions.

The paint thickness gauge is easy to use and is almost completely automatic when working on a variety of surfaces including wood, plastic, and metal. It is technologically advanced in nature due to its sleek processing procedures which measure coatings efficiently without wasting time.

Destructive coating thickness measurement:

Coating thickness is measured by taking the surface area of a specimen and dividing it by its volume. The volume can be found either by submerging the specimen in water, burning it or some other method of destruction. This is the most common method for determining coating thicknesses on materials that are not able to be part of the standard calibration.

Non-destructive coating thickness measurement:

Non-destructive methods are typically used on coated parts where destructive testing could cause expensive damage. Common non-destructive methods include ultrasonic and magnetic gauges as well as eddy-current gauges.

If you’re in the market for a coating thickness gauge, check the wide range of thickness gauges and other industrial equipment available at TestCoat. The company has built a reputation as being one of the best online stores for industrial equipment.

Know more about TestCoat products - https://www.testcoat-usa.com/

Comments

Post a Comment