Choosing the Right Inspection Equipment for the Coating and Paint Industry

HVAC, automotive, and industrial coatings companies require inspection equipment to monitor their production processes. With the rise in demand for inspection without interference from users and various stages of production, it's important to know what types of inspection equipment are available that work with this standard. This blog post provides a general overview of the types of inspection equipment.

Inspection is an essential part while manufacturing coatings (or any other material) from beginning to end because quality control is the most important thing a company can provide for its customers.

The BYK gloss meter is used to measure the degree of gloss on a surface. The higher the level of gloss, the smoother the surface. This tool is used to control and monitor different processes, such as R&D. A good quality control department uses this product during new product R&D because it can produce a quick and efficient quality check without any human interference.

When working with epoxy-based or waterborne paint, the R&D department should follow specific parameters while testing to ensure that development meets customer specifications. After the finalization of new products, BYK gloss meters are used for production runs to control quality as well as compare current production runs against previous runs.

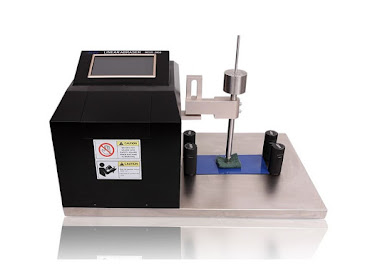

This device is used to measure the degree of washability of a given coating. During the manufacture of automotive coatings, for example, a waterfall test is performed on uncoated film and the results are compared to the final results against hand-wipe. The right device can be used for checking washability in water-based systems such as marine paints, sealants, and varnishes. Water (or any liquid) can be added to a sample area on the device and then watched as the liquid covers a certain area. This area is then measured against an analytical solution that shows how much of this solution was absorbed by the surface being tested.

In this type of device, the effect of wetting and drying on a coating is measured. In the case of coatings, the paint meter analyzes how much water was absorbed by the sample during a given time period. For example, if a 5% water-based coating is being prepared for a demonstration and it's being applied in half an hour, then it can be measured how much water-based product is left on the surface after drying. This device is used to measure the quality of coatings quickly and easily. Sometimes, depending on the device, the process involves coating small samples with test solutions that are heated to different temperatures.

Choosing the best inspection equipment:

Imaging system - an effective and efficient inspection system will provide an easier way to see problems within a coating process. If there are problems with a coating, for instance, a complex setup allows you to detect them.

This is where the main advantage of using inspection systems with imaging systems comes in: you can imagine the problem and find it easier.

Automated inspection system - Automated Inspection Systems (AIS) are also a solution for industry workers because they allow production workers to have complete control over the process in place when no humans are on site.

No matter which of the options people recommend, an industry can operate with much cheaper and more efficient solutions. What many people do not realize is that even water-based systems, such as marine coatings and sealants and varnishes, have a primary coating that is applied at stage one. This coating has to be able to withstand the production process in spite of being water-based. So even if you are using water-based products, your job will be easier if you choose a reliable inspection system that can work with your needs.

About TestCoat:

For many years, TestCoat has been a trustworthy partner and leader in the supply and distribution of inspection equipment, laboratory & physical test equipment for the coatings and paint industries. We supply non-destructive quality control and testing instruments such as Paint thickness Mil Gauges, Gloss meters, portable and benchtop metal hardness testers, laboratory mixersviscometers, film applicatorsdrying time recorder, cupping testers, Wet scrub abrasion testers, Coating inspection kits with advanced technology, and of the highest standards.

For more information, visit https://www.testcoat-usa.com/

Comments

Post a Comment