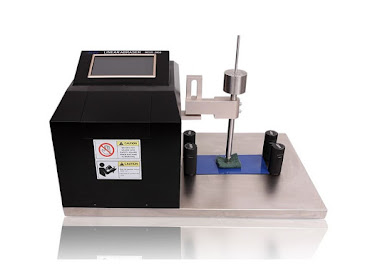

Digital Micro Vickers Hardness Testing System: Everything You Need to Know

Digital micro Vickers hardness testing system is a common way of quantifying the hardness of materials in engineering and manufacturing. This is accomplished by using a sharp object such as a diamond point or needle to scratch the surface of the material being tested in order to determine how much force is required for scratching it. In recent years there have been advancements in technology that make this process faster and more accurate while maintaining high precision for hardness measurements.

Digital micro Vickers hardness testing system-based equipment generally falls under two categories: a contact type, which touches the test material, and a non-contact type that does not touch the sample. The noncontact microhardness testers are generally more accurate. Contact instruments require the user to apply just enough force to make contact with the surface of the object being tested. With non-contact instruments, it is possible to press harder on an object that has a lower hardness level than another with a higher hardness level without contacting it. A force is applied using a Vickers indenter or diamond tip that is quite small in size. An indenter tip that looks like this can have different shapes and sizes depending on its purpose.Most digital micro Vickers hardness testing systems measure the force required to indent or scratch the material surface. Vickers indenters are a special type of diamond tip used to measure the hardness of materials. A Vickers indenter, also known as a digital microhardness tester, applies an extremely small amount of power (generally less than 1 V) and simultaneously touches the test surface with its diamond tip to achieve indents. A Vickers Indenter measures hardness in units called Vickers Units (VU). Each VU has a numerical value ranging from 0 to about 1000000. An instrument that gives readings in VU is called a digital micro Vickers hardness tester and another instrument that gives readings in grams is known as a digital micro-hardness tester.

In a digital MHL system, an integrated circuit chip is used for each measuring step. A very high-precision (100 nm) diamond tip probe generates the electrical signal which is amplified by an integrated circuit and transmitted to the display unit. At the display unit, the signal is digitized and recorded to a logarithmic scale. The data is then transmitted to a PC where it can be interpreted and displayed as the hardness value on screen. Some MHL systems also have an integrated sensor that measures the pressure applied by the diamond tip to a sample and transmits it to a PC as well.

In order for the digital micro Vickers hardness testing system to function properly and produce accurate results, all of these components must be in good working order. It's crucial that the tips are cleaned before each use. Vickers tips can be cleaned with alcohol or acetone and left overnight without any ill effects (depending on quality of the tip). Diamond tips and probes can be cleaned with alcohol or acetone as well.

The instrument is then calibrated for the first time. Calibration should be performed with both the tip and the sample holder to ensure accuracy. Calibration should be done at least every 50 readings. Proper maintenance is essential to ensure proper functioning of a digital micro-hardness tester or digital micro Vickers hardness testing system. It is important that these instruments are properly cleaned between each use and stored safely to avoid damage from temperature, humidity or other factors which could cause damage to parts within the instrument. This may also require lubrication on parts such as needle probes that will come into contact with samples in order for them to function properly.

About TestCoat:

About TestCoat:

For many years, TestCoat has been a trustworthy partner and leader in the supply and distribution of inspection equipment, laboratory & physical test equipment for the coatings and paint industries. We supply non-destructive quality control and testing instruments such as Paint thickness Mil Gauges, Gloss meters, portable rockwell hardness tester, laboratory mixersviscometers, film applicatorsdrying time recorder, cupping testers, micro tri gloss meter, Wet scrub abrasion testers, Coating inspection kits with advanced technology, and of the highest standards.

For more information, visit https://www.testcoat-usa.com/

Comments

Post a Comment